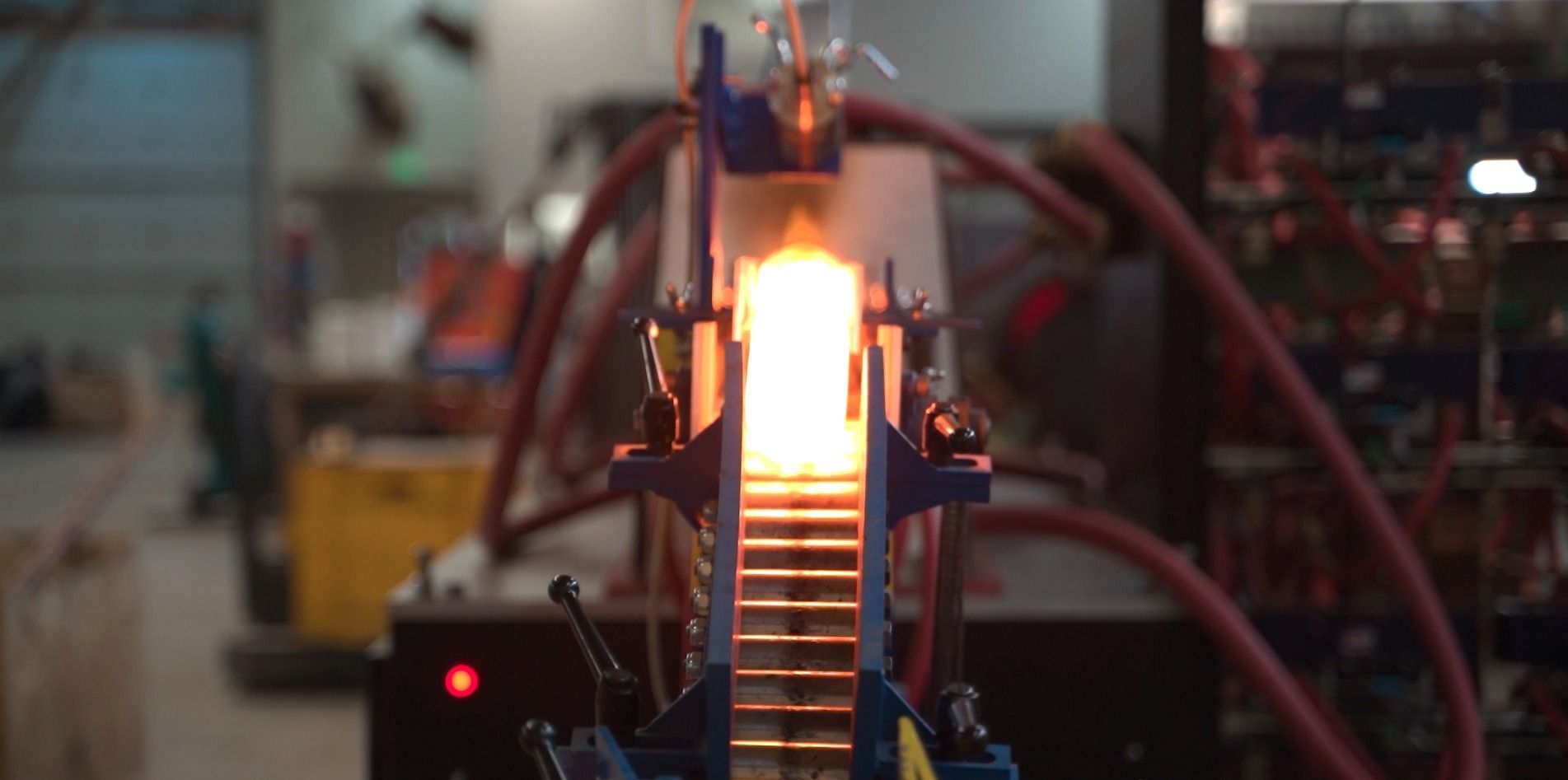

In the ever-evolving landscape of manufacturing, the push for eco-friendly practices is gaining importance. Induction heating, a technology making waves across industries, shines as a green alternative with numerous benefits. Using electromagnetic currents, induction heating rapidly warms metal, ensuring precise and controlled heating without direct contact. ThermESC induction heating technology offers speed and accuracy without resorting to open flames or fuel combustion.

Let 's explore ten advantages driving its adoption and reshaping manufacturing landscapes:

Improved Energy Efficiency

One of the primary green benefits of induction heating is its exceptional energy efficiency. Unlike traditional heating methods such as gas or flame heating, induction heating directly transfers energy to the material being heated, minimizing heat loss. This efficiency results in lower energy consumption, ultimately reducing the carbon footprint associated with manufacturing processes. Beyond its direct impact on energy consumption, induction heating also contributes to energy conservation by eliminating the need for preheating or extended warm-up periods. This aspect further enhances the overall operational efficiency. With ThermESC, the manufacturing processes are made exponentially more efficient.

Reduced Emissions

Induction heating's eco-friendly profile extends beyond its minimal emissions. Unlike conventional heating methods that often rely on fossil fuels, induction heating operates without open flames or combustion processes. This not only minimizes the release of harmful pollutants into the atmosphere but also reduces the carbon footprint associated with the extraction, transportation, and consumption of fossil fuels. After-all, Induction heating is all about keeping things clean in manufacturing. With ThermESC we ensure the manufacturers remain eco-friendly and stay on top of the changing environmental rules.

Precision in Heating Control

Induction heating provides precise temperature control, allowing manufacturers to heat specific areas as needed. This accuracy minimizes waste and prevents overheating, making resource use more efficient. Precise heat targeting also boosts the overall quality of manufactured products. It ensures each component gets the exact characteristics needed for top-notch performance, meeting high standards and customer expectations. This precision sets the stage for consistent, reliable, and excellent end results. Therefore, ThermESC believes induction heating is not only a plus point but crucial for precise manufacturing.

Shorter Processing Times

Induction heating significantly reduces heating and processing times compared to traditional methods. The rapid and efficient heat transfer enables manufacturers to streamline production processes, resulting in increased productivity. Shorter processing times not only enhance operational efficiency but also contribute to energy savings and reduced environmental impact.

Extended Equipment Lifespan

Induction heating isn't just about making equipment last longer; it's also about lessening the impact on the environment from making and getting rid of them. Because the heating source doesn't directly touch the material being processed, tools and equipment have way less wear and tear. This keeps them going for much longer, so there's less need to replace them all the time. With ThermESC not only do manufacturers save money, but having equipment stick around longer also makes the whole manufacturing process more eco-friendly.

Resource Conservation

The precise and focused heating power of induction heating is a game-changer for resource conservation. Manufacturers can cut down on materials since there's minimal waste during heating. This not only trims raw material use but also reduces the energy needed for material production, highlighting induction heating's eco-friendly edge.

Improved Workplace Safety

Induction heating offers a safer working environment compared to traditional heating methods. With no open flames or hot surfaces, the risk of accidents, such as fires or burns, is significantly reduced. This not only protects the well-being of workers but also mitigates potential environmental damage resulting from workplace incidents.

No Combustion Byproducts

Unlike combustion-based heating methods, induction heating produces no combustion byproducts such as ash, smoke, or particulate matter. Without these pollutants, the air quality at workplaces gets a serious upgrade, so no need for those pricey and environment-hassling emissions control systems. After all, cleaner air isn't just good for the planet, it's also a solid win for the people on the production line.

Versatility and Adaptability

Induction heating stands out as a flexible technology that seamlessly fits into different manufacturing processes. Whether it's for brazing, annealing, or hardening, induction heating systems are adjustable to meet precise heating needs. This flexibility empowers manufacturers to fine-tune their processes, curbing waste and minimizing energy usage across various applications.

Reduced Carbon Footprint

By blending all the mentioned advantages, induction heating actively lessens the carbon footprint of manufacturing. The mix of energy efficiency, diminished emissions, and resource conservation positions induction heating as an eco-friendly technology in sync with the global push for sustainable manufacturing practices.

Conclusion

Induction heating not only maintains quality but also improves productivity. Rapid heat transfer reduces processing times, meeting industry demands for efficiency without compromising component integrity. This not only ensures timely deliveries but also contributes to energy savings.

Choosing induction heating is a smart move for manufacturers eyeing growth. It's like giving your industry a boost—saving energy, cutting waste, and keeping things eco-friendly. With induction heating, your business doesn't just survive; it thrives in a greener and more efficient future. ThermESC works round the clock to guide manufacturers in making smart choices.

For more information or to get a quote, give us a call at 970-483-5232 or visit our website at

https://www.thermesc.com/