Top 10 Industries Benefiting Most from Induction Heating Solutions

ESC Induction

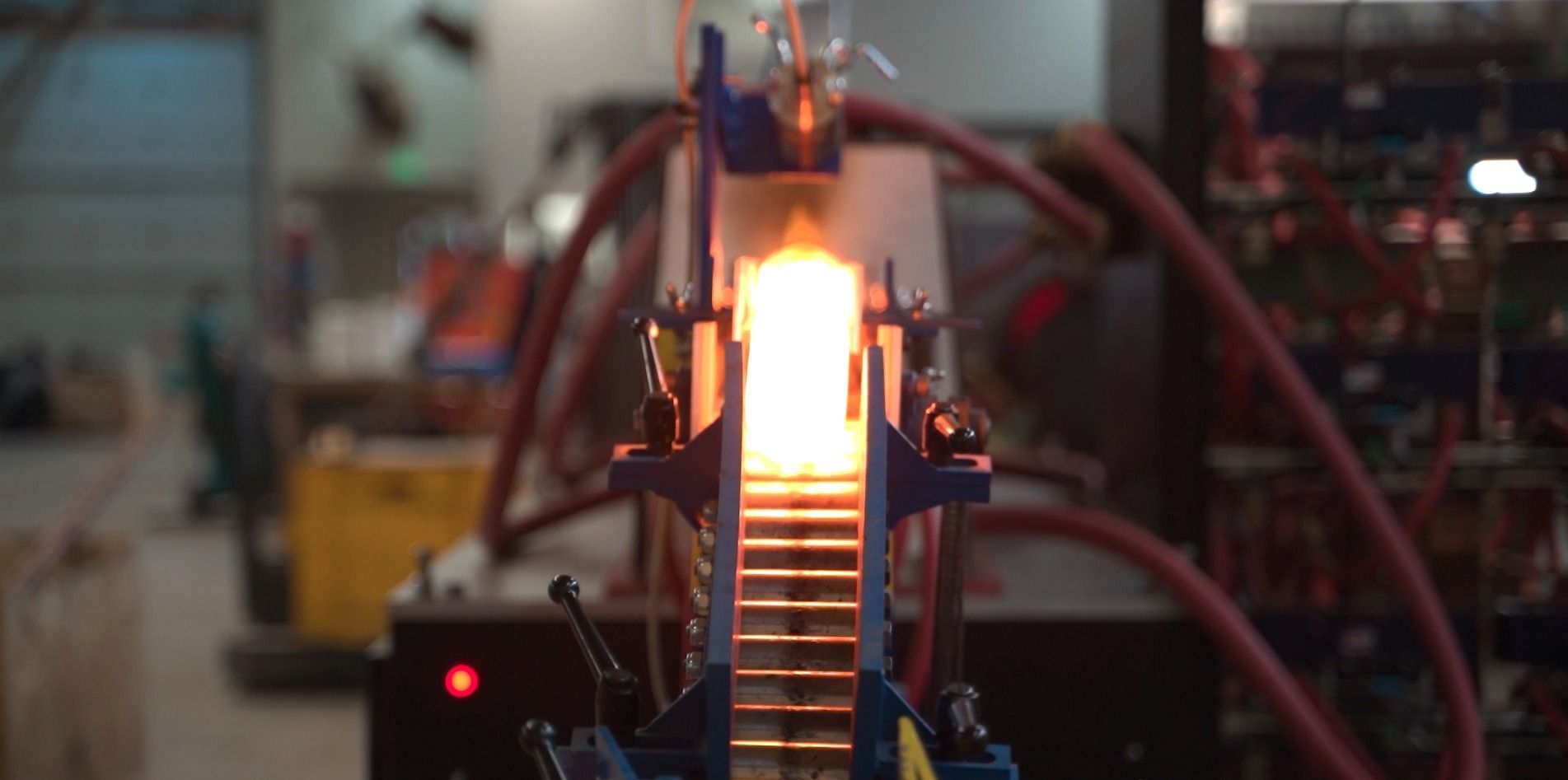

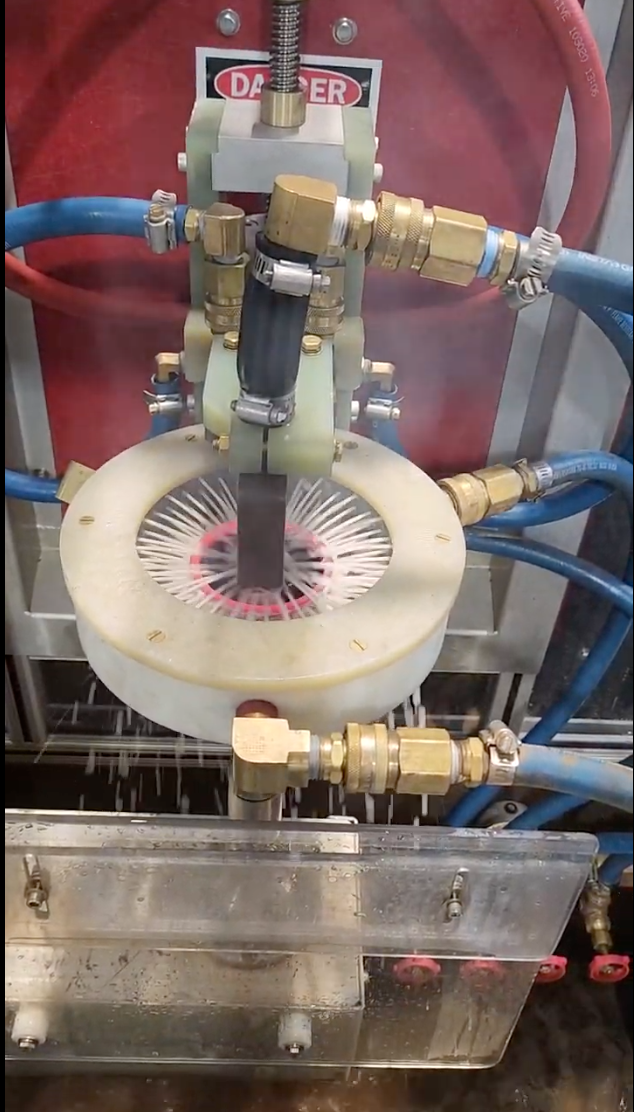

Induction heating

is revolutionizing the way manufacturers approach thermal processes, offering a cleaner, more precise, and energy-efficient alternative to traditional heating methods. This advanced technology harnesses electromagnetic fields to heat metal components without direct contact or open flames—making it a powerful tool for modern industry.

Whether you're forging, brazing, soldering, or performing heat treatment , the benefits of induction heating include faster cycle times, improved safety, and reduced energy consumption. As manufacturers seek sustainable and cost-effective solutions, the demand for industrial induction heating systems continues to grow.

Whether you're forging, brazing, soldering, or performing heat treatment , the benefits of induction heating include faster cycle times, improved safety, and reduced energy consumption. As manufacturers seek sustainable and cost-effective solutions, the demand for industrial induction heating systems continues to grow.

From custom forging lines to portable induction heating for on-site maintenance, ThermESC Intl. leads the charge with scalable, application-specific solutions that deliver measurable ROI. Below, we explore the

top 10 sectors currently reaping the most rewards from induction heating technology:

- Automotive – Used for hardening components like gears, axles, and crankshafts, induction heating ensures durability and precision in mass production.

- Aerospace – Lightweight, high-performance materials require controlled, non-contact heating, making induction ideal for composite bonding and metal hardening.

- Oil & Gas – Induction heating is used in pipe welding, stress relieving, and heat treating to enhance safety and performance under extreme conditions.

- Power Generation – Boiler tube removal and component maintenance are simplified with portable induction systems, reducing downtime and labor.

- Manufacturing & Heavy Industry – Forging lines, heat treating, and brazing benefit from precise, repeatable heat control.

- Electronics – Soldering components with induction offers clean and reliable joints without risk of damage to nearby circuitry.

- Railroad – Wheel and axle repairs, bearing heating, and other maintenance tasks are completed faster and safer with induction.

- Shipbuilding – Used for hull and engine part assembly, this method ensures reliable, efficient joins under high demand.

- Construction – Induction is used for rebar coating and bolt heating, improving safety and installation times.

- Renewable Energy – Induction plays a role in wind turbine maintenance and component manufacturing with reduced environmental impact.

With customizable induction heating systems and accessories from ThermESC Intl., companies across these sectors can elevate their productivity, reduce downtime, and meet today's industrial efficiency standards while preparing for tomorrow's sustainability goals.

In the ever-evolving landscape of manufacturing, the push for eco-friendly practices is gaining importance. Induction heating, a technology making waves across industries, shines as a green alternative with numerous benefits. Using electromagnetic currents, induction heating rapidly warms metal, ensuring precise and controlled heating without direct contact. ThermESC induction heating technology offers speed and accuracy without resorting to open flames or fuel combustion. Let 's explore ten advantages driving its adoption and reshaping manufacturing landscapes: