Induction

Heating, Cooling, Coils

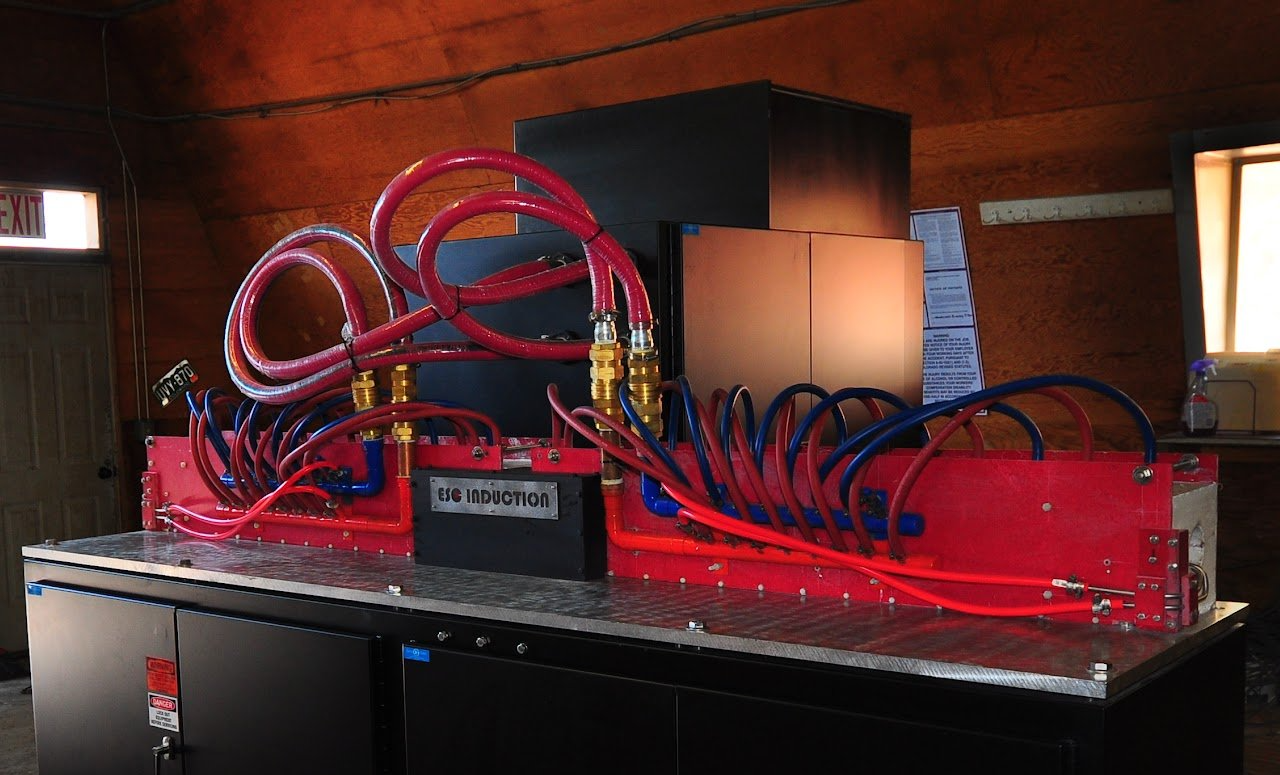

Every machine that ESC that leaves our door is custom designed with your process in mind

All of our Induction Heaters are centered around a PLC (Programmable Logic Controller). The PLC

includes a color touch screen to control the Induction Equipment. Power control and heat start/stop are available on the touch screen, or a remote operator panel. The PLC also contains a fault history log for ease of troubleshooting. PLCs have been utilized for several years in industrial

applications due to their reliability. ESC Induction has taken advantage of the PLC’s reliability and ease of use for an operator/service person and minimized the need for custom circuit boards, thereby improving the customer’s uptime, making your company more productive.

Recipe selection is provided when applicable. Recipes can be protected from misadjustment with a secure password such that the operator cannot adjust variables. Only personnel with the password are capable of adjusting recipe variables. The PLC can control all facets of a turn-key system. By having a PLC we are capable of full automation or semi-automation without the need of a separate control system. The PLC can also be designed for manual operation.

Induction Coils designed for optimum efficiency and reliability

With expertise and experience in the Induction industry, we can design a new robust and efficient

coil, or re-design and rebuild your existing coil to improve efficiency and longevity.

- Custom Builds

- Refurbishment

- Application &

- Design Assistance

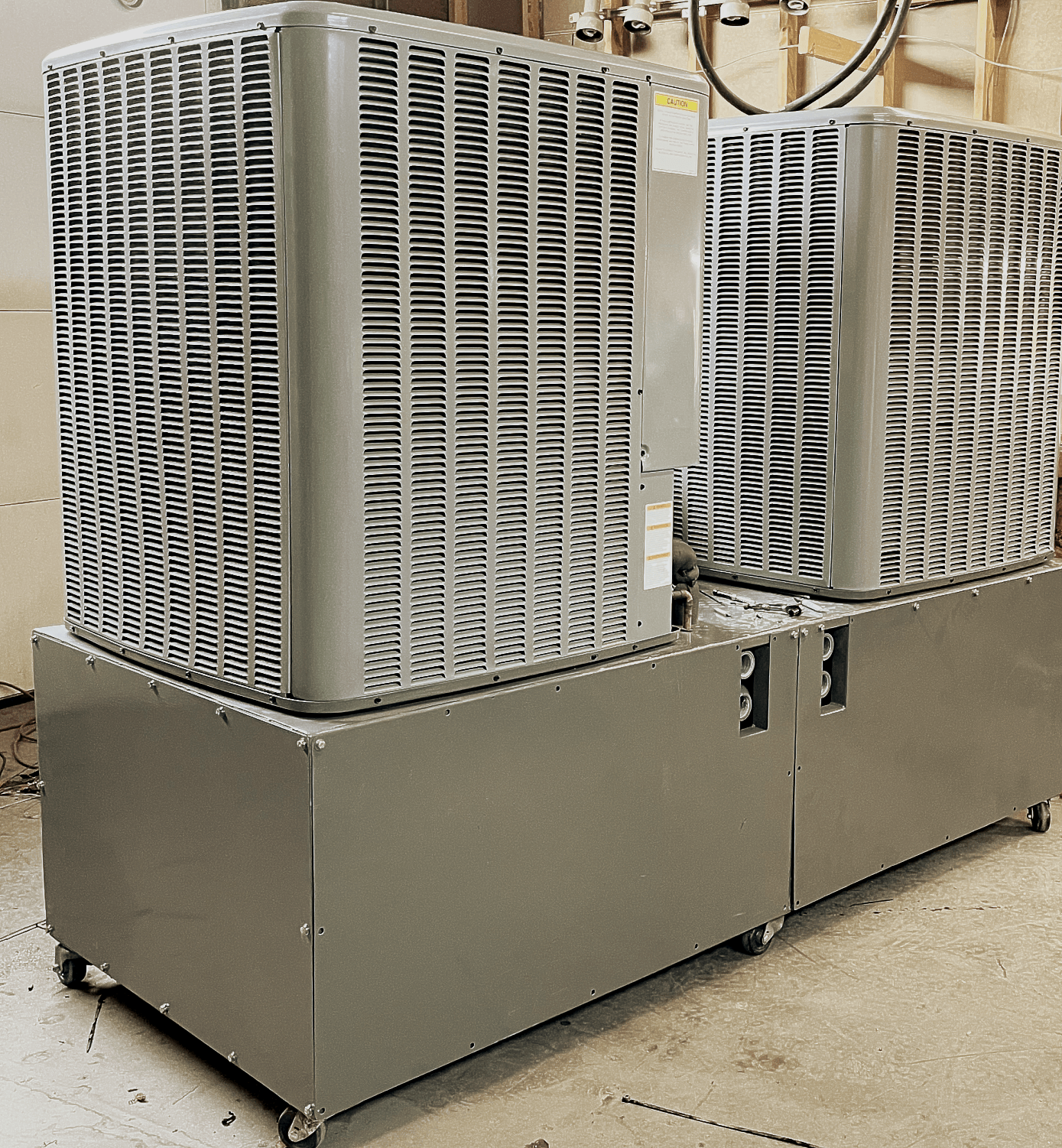

Find the right cooling system for your needs

Water is the life blood of every induction machine.

Maintaining low conductivity and clean water makes for a long a dependable induction machine. Our distilled water systems and chillers will keep your induction functioning at its highest performance.

CONTACT US

Want more info?

Contact Us

We will get back to you as soon as possible.

Please try again later.

See us in person

6104 County Road F, Wiggins, CO, 80654, United States

Contact us

Mailing Address

ESC Induction

PO Box 1453

Fort Morgan, CO 80701

All Rights Reserved | ESC Induction | Website by CJ Designs