Explore the Possibilities

Our Services

List of Services

-

PREVENTATIVE MAINTENANCE We offer preventative maintenance programs to find and resolve issues before malfunction occur. This allows you to choose your downtime based on workload rather than failing while production is critical. PREVENTATIVE MAINTENANCE

-

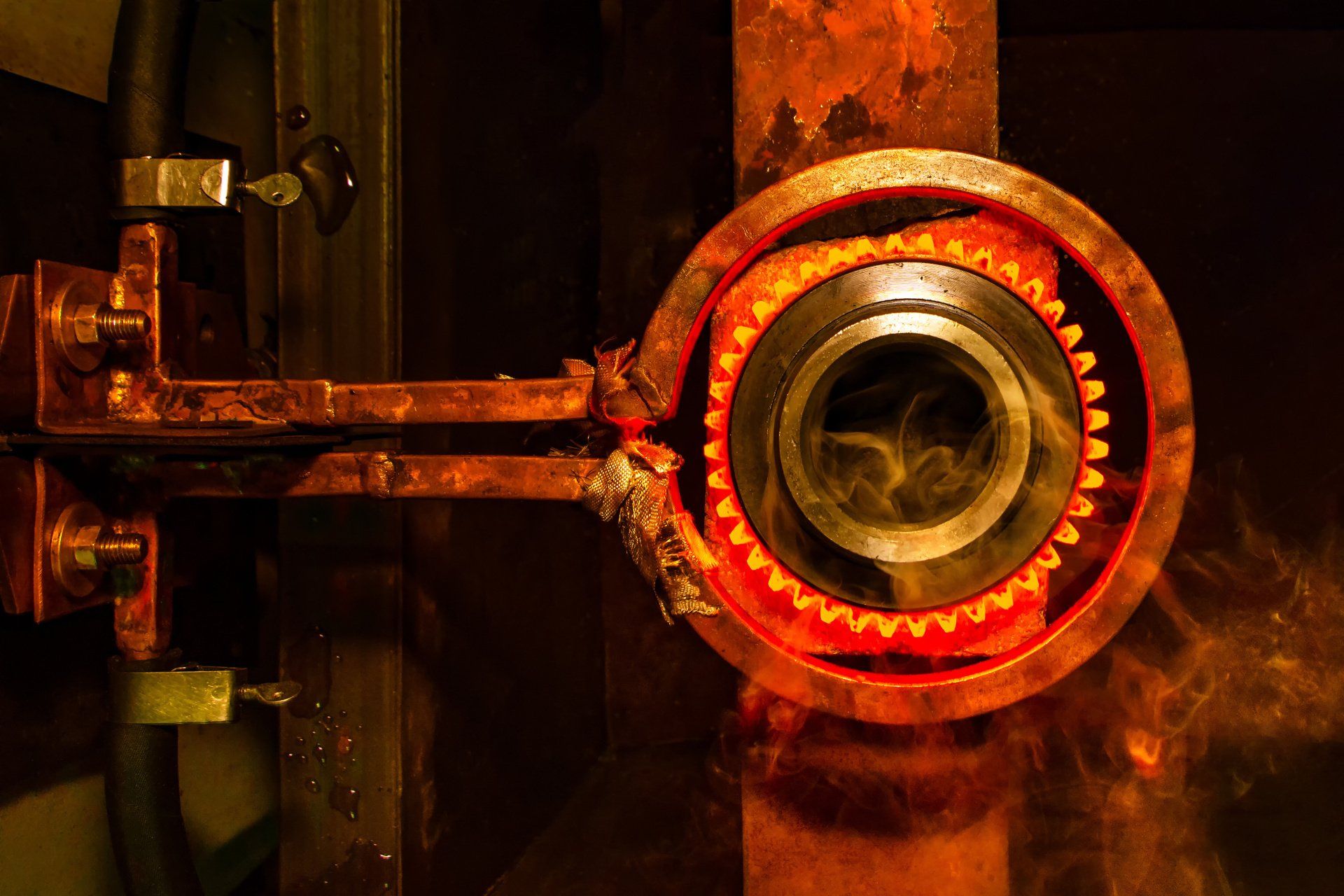

TRANSFORMER REBUILDS We offer water-cooled transformer repair and refurbishing, including Jackson Transformer® and Hunterdon Transformer®.TRANSFORMER REBUILDS

-

EMERGENCY SERVICE CALLS Highly trained and professional field service personnel will get your equipment running quickly.EMERGENCY SERVICE CALLS

-

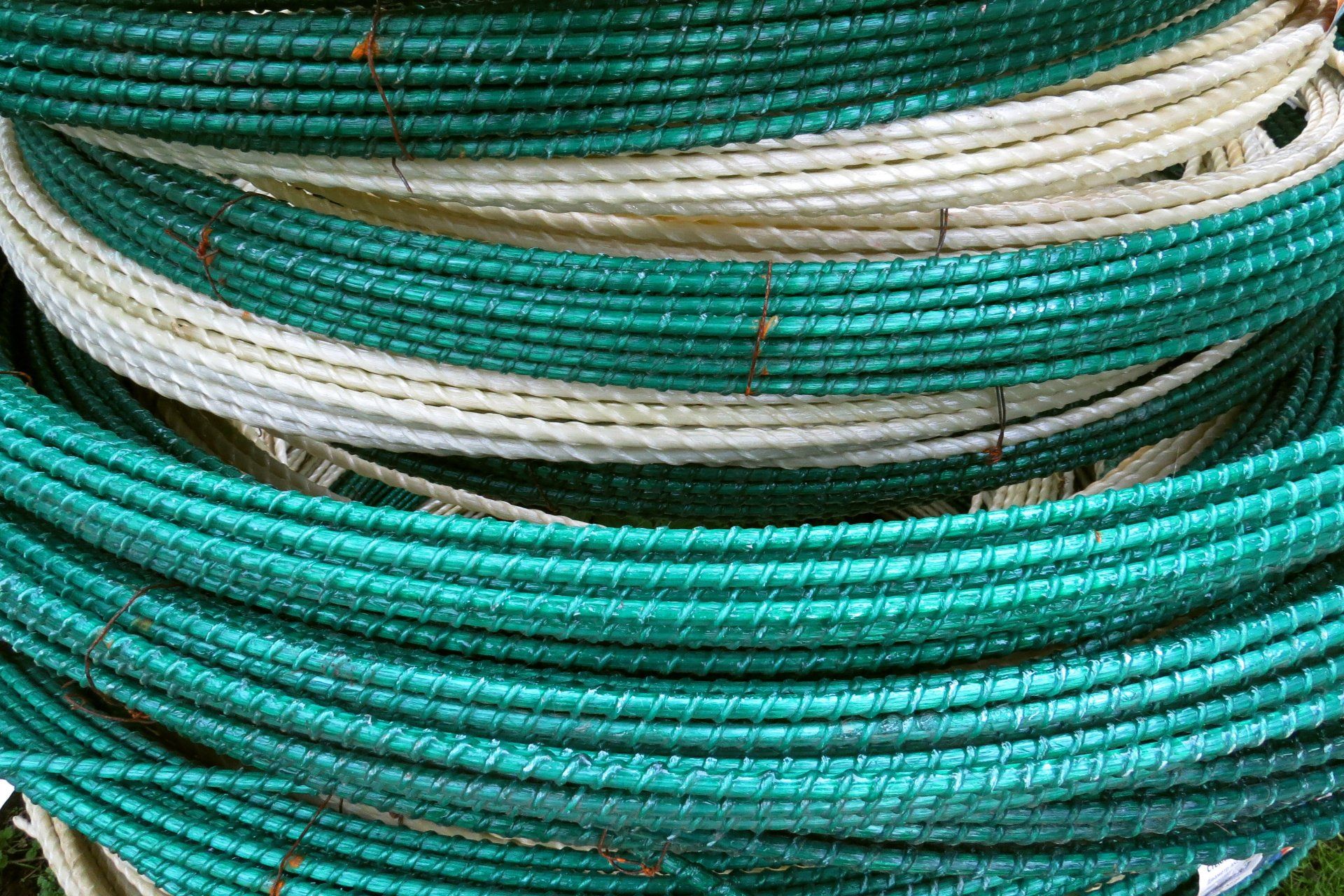

COIL REBUILDS Send your coil to us for rebuilding. We offer quick turn around and return your coil in like-new condition. COIL REBUILDS

-

CUSTOM INDUCTION SYSTEMS Custom, PLC controlled induction heating and cooling systems designed specifically with each customers production needs at the forefront.CUSTOM INDUCTION SYSTEMS